Crane operations are vital to construction. They enable precise, efficient handling of heavy materials. These operations face significant challenges from external elements. Weather is one of the most impactful. Construction managers, crane operators, and safety staff must know how weather affects crane work. This is to reduce risks and keep efficiency high.

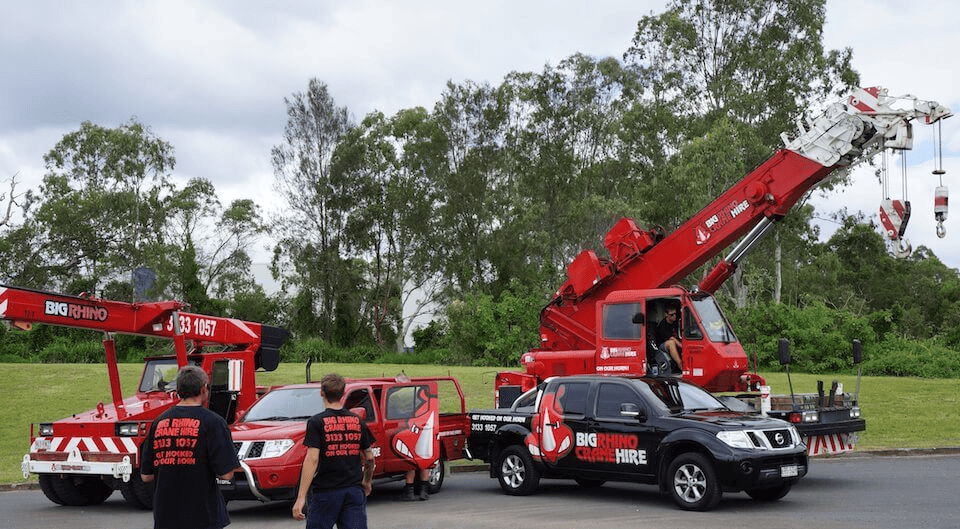

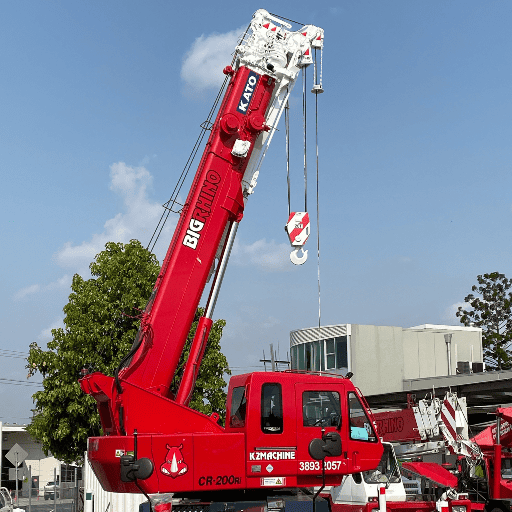

Cranes can significantly reduce the time and cost of heavy lifting tasks. At Big Rhino Crane Hire, ensuring safety is our utmost priority. Bad weather can damage equipment and injure nearby people. So, at Big Rhino, we train our operators to watch for weather changes. They know when to stop work to stay safe. In the face of uncertain weather, exercising caution is essential.

The Importance of Weather in Crane Operations

Weather significantly impacts crane operations, affecting safety, efficiency, and project timelines. So, we must understand its effects. This is key for planning, risk management, and ensuring people’s and equipment’s safety.

Safety First

Weather is key to safety on construction sites, especially with cranes. High winds, for example, can pose a serious risk. Cranes have specific wind speed limits. Exceeding these limits can result in dangerous situations such as tipping or load swinging. Operators must be vigilant and aware of sudden weather changes to avoid accidents.

Equipment Performance

Extreme temperatures—whether hot or cold—can affect the performance and longevity of crane equipment. Hydraulic systems struggle in temperature extremes. Cold makes them slow; heat risks overheating and breakdowns. Weather impacts performance significantly. Cranes need regular maintenance checks and weather-based adjustments. This is vital for their smooth operation.

Project Timelines

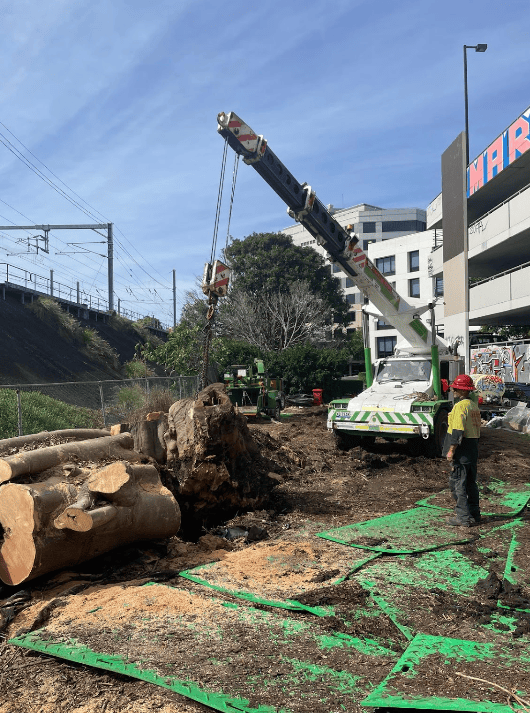

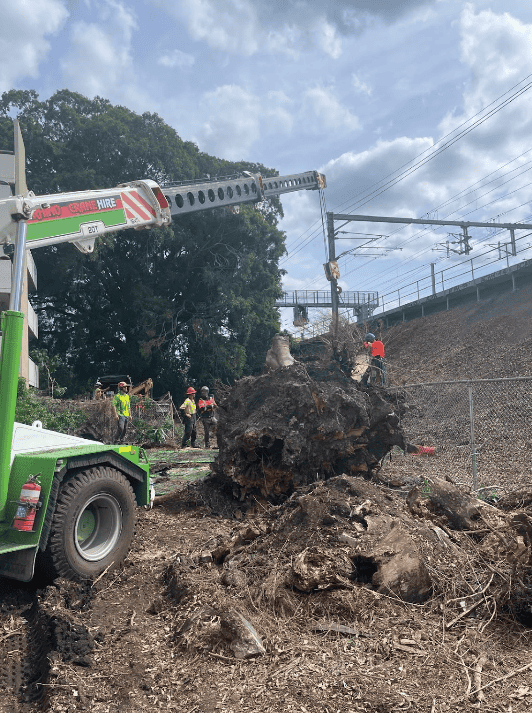

Unpredictable weather can lead to delays in construction schedules. Rain, snow, or fog can limit visibility and affect ground conditions, making it unsafe for crane operations. Where possible we can reduce weather-related delays by using weather forecasts. However, flexibility should always be built into project timelines, to allow for any unexpected weather events.

Risk Management

Effective risk management strategies must include weather considerations. This involves not only monitoring forecasts but also having contingency plans in place. It is vital to train crane operators to respond to sudden weather changes. Regular safety drills are also important. They help manage weather-related risks.

Impacts of Different Weather Conditions on Crane Safety

Wind

Wind is one of the most significant weather-related risks in crane operations. High winds can cause loads to sway or become unbalanced, increasing the risk of tipping or dropping the load. Even a light breeze can have a significant impact when lifting large surface area loads, such as panels or signage.

- Mitigation: We set wind speed limits for operations, and train all operators to recognize unsafe wind conditions.

Rain and Snow

Rain or snow can make surfaces slippery. This reduces traction and increases the chance of equipment slippage. Wet conditions can also affect the mechanical components of cranes, leading to potential failures.

- Mitigation: Our cranes are equipped with anti-slip materials. We also check and maintain them regularly to reduce moisture’s impact on their mechanical parts. Our team plan operations around heavy precipitation days when possible.

Temperature Extremes

Both high and low temperatures can affect crane operations. Cold can make materials brittle. Extreme heat can overheat equipment or cause it to malfunction.

- Mitigation: Big Rhino Crane Hire Operators use equipment designed for extreme temperatures and perform regular maintenance checks. This ensures everything works well. We also train operators to identify signs of temperature-related stress in the equipment.

Lightning

Lightning poses a direct threat to crane operations, as cranes are often the tallest structures on a site. The risk of lightning strikes can lead to severe consequences, both in terms of human safety and equipment damage.

- Mitigation: Stop all operations during electrical storms. Properly ground cranes to prevent lightning strikes. Implement a comprehensive emergency response plan for lightning events.

Best Practices for Crane Operations in Challenging Weather

Regular Training and Drills:

- Train operators and safety teams to recognize and respond to bad weather.

- Simulate weather-related emergencies to ensure readiness.

Weather Monitoring Systems:

- Invest in reliable weather systems. They must provide real-time, site-specific data and forecasts.

- Use this data to make informed decisions about when to postpone or proceed with operations.

Communication Protocols:

- Set clear protocols for quickly sharing weather information across teams.

- Use radios or digital communication tools to maintain constant contact with crane operators.

Scheduled Inspections and Maintenance:

- Implement a routine inspection schedule that includes checks for weather-related wear and tear.

- Address maintenance issues promptly to prevent the weather from exacerbating existing problems.

Preparing for Future Weather Challenges in Crane Operations

Looking ahead, construction managers and crane operators must prepare for new weather challenges.

Climate Change Impacts: With changing weather patterns, expect more frequent extreme weather events. Proactive planning and adaptive strategies will be crucial.

Collaborative Efforts: Encourage industry stakeholders to share insights and best practices for dealing with bad weather.

Continuous Improvement: Foster a learning culture to stay ahead of weather-related challenges.

Conclusion

Weather conditions undeniably shape the landscape of crane operations. By knowing the impacts and using good strategies, construction managers, crane operators, and safety pros can ensure safe operations. They can succeed, no matter what Mother Nature throws their way.

For those in the industry, staying informed and prepared is key. The goal is the same, no matter the method. Use new tech or best practices. We want efficient, safe, and cost-effective crane operations that drive project success.